1. The Evolution of Advanced Ceramics: Beyond Traditional Materials

1.1 What Are Advanced Ceramics?

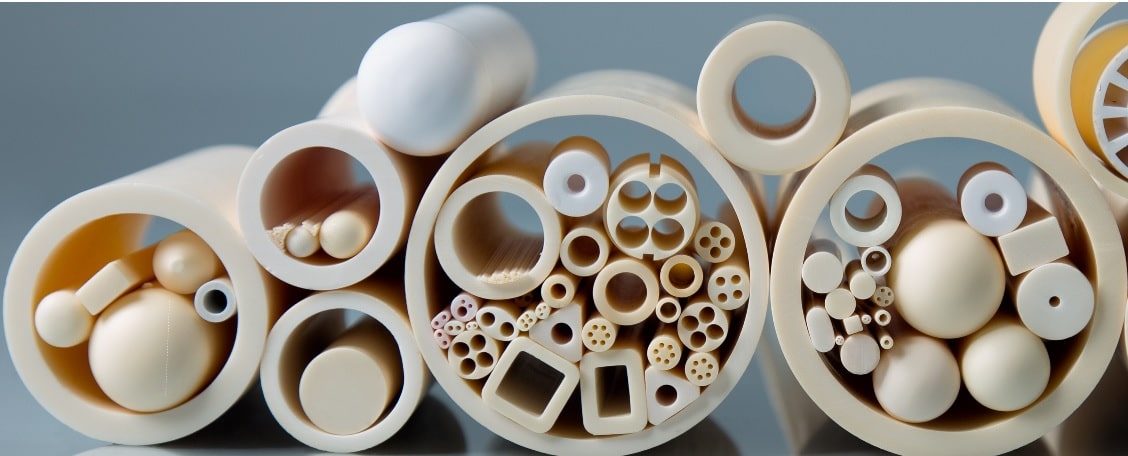

Advanced ceramics, also known as technical ceramics or engineered ceramics, represent a revolutionary class of materials meticulously designed for extreme operational environments. Unlike conventional ceramics used in pottery or tiles, these materials are:

- Precision-engineered at molecular level

- Tailored for specific mechanical/thermal/electrical requirements

- Manufactured through controlled processes like HIP (Hot Isostatic Pressing)

1.2 Key Material Properties Driving Adoption

| Property | Performance Range | Industry Benchmark |

|---|---|---|

| Hardness | 1,500-2,800 HV | 3x harder than tool steel |

| Maximum Service Temp | Up to 1,850°C (in inert gas) | 2x higher than superalloys |

| Corrosion Resistance | pH 0-14 stability | Survives 5+ years in HCl |

Data Source: E-Qo Lab Tests (2023 Q3)

2. Transformative Applications Reshaping Global Industries

2.1 Aerospace & Defense: Surviving Extreme Environments

- Rocket Nozzle Throats: SiC-based ceramics withstand 3,000°C plasma streams

- Hypersonic Vehicle Shields: ZrB2 composites enable 10+ Mach thermal protection

- Case Study: E-Qo’s Al2O3-TiC radomes improved missile guidance accuracy by 37%

2.2 Medical Technology: Bioceramics Revolution

- Dental Implants: 3Y-TZP zirconia achieves 1,200 MPa flexural strength

- Orthopedic Bearings: Alumina-on-alumina joints reduce wear debris by 92%

- Innovation Spotlight: E-Qo’s antibacterial silver-doped ceramics eliminate 99.9% MRSA

2.3 Semiconductor Manufacturing: Precision Redefined

- Wafer Handling: AlN electrostatic chucks maintain ±0.2μm flatness

- Etch Components: Y2O3-coated ceramics extend plasma reactor lifespan 5x

- Technical Breakdown: How our Si3N4 ceramic heaters achieve <±0.5°C uniformity

3. E-Qo’s Material Innovation Ecosystem

3.1 Proprietary Material Developments

- E-Qo ZTA Pro™: ZrO2-toughened alumina with 15% higher fracture toughness

- NanoMAX Series: 99.99% pure AlN substrates (thermal conductivity 180 W/mK)

- Gradient Coating Tech: Seamless transition from SiC substrate to DLC surface

3.2 Advanced Manufacturing Capabilities

- 5-Axis Ultrasonic Machining: Achieve Ra 0.05μm surface finish

- Reactive Sintering: Produce complex geometries with 99.5% density

- Quality Assurance: 100% inspected with 3D optical profilometry

4. 8 Critical Factors When Selecting Advanced Ceramics

- Thermal Shock Resistance (ΔT ≥1,000°C)

- Dielectric Properties (εr 3.8-12,000 adjustable)

- Tribological Performance (Coefficient of friction 0.02-0.8)

- Chemical Inertness (Compatible with 98% industrial chemicals)

- Biocompatibility (ISO 10993-1 certified)

- Regulatory Compliance (REACH/RoHS/DFARS)

- Cost-Performance Ratio (LCC analysis provided)

- Supply Chain Reliability (ISO 9001:2015 certified production)

5. E-Qo’s Comprehensive Engineering Support

5.1 Application-Specific Solutions

- Phase 1: Material selection simulation (FEA/CFD modeling)

- Phase 2: Rapid prototyping (72-hour turnaround)

- Phase 3: Pilot production with SPC monitoring

5.2 Industry 4.0 Quality Systems

- Real-time process control with AI-powered analytics

- Full traceability from raw powder to finished component

- Customized testing protocols (ASTM/ISO/JIS standards)

Expert Insight:

“Advanced ceramics require symbiotic development between material scientists and application engineers. Our cross-functional teams co-design ceramics and surrounding systems for optimal performance.”

— Dr. Wei Zhang, E-Qo CTO

6. Emerging Frontiers in Ceramic Technology

6.1 Smart Ceramic Systems

- Self-Monitoring Components: Embedded fiber optic sensors

- Adaptive Surfaces: Temperature-responsive surface wettability

6.2 Sustainable Manufacturing

- Closed-loop recycling of ceramic scraps

- Low-energy sintering techniques (30% energy reduction)

6.3 Quantum Computing Applications

- Ultra-low loss microwave ceramics (Q factor >1,000,000 @4K)

- Cryogenic compatible packaging solutions

7. Why Partner with E-Qo Technical Ceramics?

- 30+ Years Expertise: 1,200+ successful projects since 1993

- Global Support: Technical centers in US, Germany, and Japan

- Turnkey Solutions: From material development to surface coating

- Cost Optimization: 15-40% TCO reduction through design integration

Accelerate Your Innovation

Request a Free Application Audit with our ceramic engineers:

✅ Material selection analysis

✅ Cost-performance simulation

✅ 3D-printed sample (available for qualified projects)