Imagine trying to sculpt a intricate porcelain figurine with a sledgehammer. That’s what traditional ceramic forming can feel like in today’s era of micro-engineered components. At E-Qo Tech, we’ve witnessed firsthand how Ceramic Injection Molding (CIM) is rewriting the rules of precision manufacturing. But does this mean old-school methods are obsolete? Let’s dissect both worlds—no marketing fluff, just hard facts.

What Is Ceramic Injection Molding (CIM)?

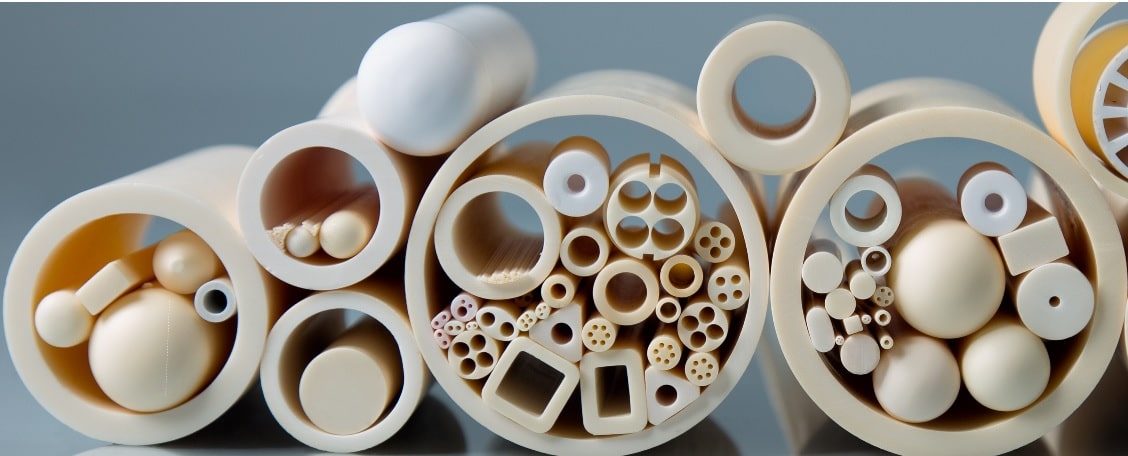

CIM isn’t your grandma’s pottery class. Think of it as the 3D printing of advanced ceramics—but with nanometer-level precision. This process blends fine ceramic powders with polymer binders, injects the mixture into molds, and sinters it into dense, complex parts.

The 4-Step CIM Process Explained

- Feedstock Preparation: Mixing alumina or zirconia powders with thermoplastic binders (like baking a high-tech cake batter).

- Injection Molding: Shooting the mixture into steel molds under 10,000 psi pressure (yes, stronger than a hippo’s bite).

- Debinding: Slowly burning away the binder—a 48-hour chemical “detox” for ceramics.

- Sintering: Firing parts at 1,600°C to achieve diamond-like density.

Why CIM Is Revolutionizing Precision Engineering

- Creates hair-thin walls (0.2 mm) impossible with dry pressing.

- Achieves ±0.1% dimensional accuracy—crucial for semiconductor substrates.

- Enables mass production of fractal-like geometries for rocket nozzles.

Traditional Ceramic Forming Methods: A Legacy Approach

Before CIM, engineers relied on methods as old as the pyramids. Let’s dust off the history books.

Dry Pressing: Simplicity vs. Limitations

- How it works: Compress powder in a die like a ceramic waffle iron.

- Pros: Cheap for simple shapes like tiles.

- Cons: Struggles with undercuts. Ever tried pressing a spiral staircase? Exactly.

Isostatic Pressing: Uniformity at a Cost

- Process: Apply equal pressure from all sides using fluid (like a ceramic spa treatment).

- Strengths: Great for large crucibles in metallurgy.

- Weaknesses: 20% material waste and 2-week lead times. Ouch.

Slip Casting: The Artisan’s Choice

- Technique: Pour liquid clay (slip) into plaster molds—pottery 101 meets R&D.

- Niche uses: Still preferred for ornate insulators in vintage electronics.

- Speed issue: Requires 12+ hours per part. Not exactly Amazon Prime delivery.

Head-to-Head Comparison: CIM vs. Traditional Methods

Let’s settle this like a gladiatorial match—data as our weapons.

Complexity & Design Freedom: Who Wins?

- CIM: Crafts lattice structures for bone implants that mimic human trabeculae.

- Traditional: Limited to basic geometries. Trying to make a helix? Good luck.

Cost Analysis: Short-Term vs. Long-Term Value

| Factor | CIM | Dry Pressing |

|---|---|---|

| Tooling Cost | $20,000-$50,000 | $5,000-$10,000 |

| Per-Piece Cost | $1.50 (10k+ units) | $3.00 (low volumes) |

| Takeaway: CIM pays off after 5,000 units—the crossover point for ROI. |

Production Speed: Batch vs. Mass Manufacturing

- CIM: 1,000 parts/day once molds are ready.

- Slip Casting: 50 parts/day with manual labor.

- Verbatim from E-Qo’s Lab: “One aerospace client cut lead times from 6 months to 3 weeks using CIM.”

Material Waste: Sustainability Showdown

- CIM: <5% scrap through binder recycling.

- Isostatic Pressing: 15-20% wasted powder.

- Earth Day bonus: CIM’s lower energy use per kg—1.8 kWh vs. 3.4 kWh for dry pressing.

Industry Applications: Where Each Method Shines

Medical Implants: Why CIM Dominates

Your new zirconia dental crown? Likely CIM-made. The method delivers:

- Bio-compatibility: Zero pores means no bacteria hideouts.

- Mass customization: 500 unique knee implant designs monthly at E-Qo’s Changzhou facility.

Automotive Sensors: Traditional Methods Hold Their Ground

Thick-film oxygen sensors still use dry pressing because:

- Cost: $0.80/sensor vs. $2.50 for CIM.

- Tolerance: ±2% suffices for exhaust systems.

The Future of Ceramic Manufacturing: E-Qo Tech’s Vision

AI-Driven CIM: The Next Frontier

We’re piloting neural networks that:

- Predict sintering shrinkage within 0.05% accuracy.

- Auto-adjust debinding times based on part thickness.

- Reduce trial runs from 10 to 2—saving $15k per design.

Can Traditional Methods Survive Automation?

Hybrid approaches are emerging:

- Robotic dry pressing: 30% faster, still limited to simple shapes.

- CIM for prototyping + traditional for bulk: A “best of both worlds” model.

Conclusion: Choosing the Right Method for Your Project

Here’s your cheat sheet:

✅ Choose CIM if: You need complex geometries, tight tolerances, or volumes >5k units.

✅ Stick to traditional if: Making simple shapes in small batches, or nostalgia is your jam.

At E-Qo Tech, we don’t just sell ceramics—we engineer possibilities. Whether you’re building Mars rovers or toaster insulators, let’s match the method to your madness.

Ready to bend the rules of ceramics? Contact E-Qo’s engineers for a free process consultation.