Introduction

In high-speed textile manufacturing, interlacing air jets are critical for creating uniform yarn entanglement, ensuring smooth downstream processing. Traditional metal nozzles, however, struggle with wear, energy inefficiency, and inconsistent performance. At E-Qo Tech, we engineer advanced ceramic interlacing air jets that redefine reliability and efficiency for modern textile machinery.

The Science Behind Interlacing Air Jets

1.1 What is an Interlacing Air Jet?

An interlacing air jet uses compressed air to entangle synthetic filaments, creating cohesion in multifilament yarns. Key functions include:

- Yarn Stabilization: Prevents filament separation during weaving/knitting.

- Quality Enhancement: Reduces yarn hairiness and improves dye uptake uniformity.

- Process Speed: Enables machinery to operate at 1,200+ meters/minute.

1.2 Limitations of Metal Nozzles

- Abrasive Wear: Polyester/Nylon fibers erode steel nozzles within 3-6 months.

- Energy Loss: Turbulent airflow in metal channels wastes 25-30% compressed air.

- Thermal Deformation: High-speed operations cause dimensional instability.

Why Ceramic Interlacing Jets Outperform

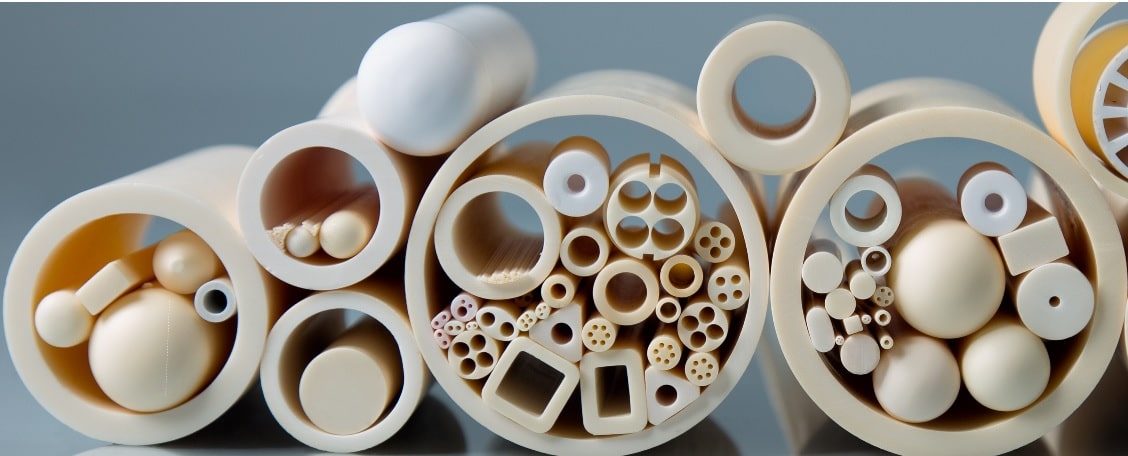

2.1 Zirconia-Toughened Alumina (ZTA) Nozzles

E-Qo Tech’s ZTA ceramic nozzles deliver:

- Hardness: 1,500 HV (3x harder than stainless steel)

- Wear Resistance: 18+ months lifespan in abrasive environments

- Airflow Precision: Laser-drilled channels with ±0.02mm tolerance

Explore our ceramic interlacing air jet solutions for Barmag, Rieter, and Toyota machines.

2.2 Silicon Carbide (SiC) Components

- Thermal Stability: Withstand 450°C continuous operation

- Energy Efficiency: 30% lower air consumption vs. metal nozzles

- Custom Designs: Adapt channel geometry for polyester, nylon, or blended fibers

Case Study: Boosting Efficiency in a Vietnamese Polyester Mill

Challenge:

- Frequent nozzle replacements (every 4 months)

- 12% yarn breakage due to inconsistent entanglement

Solution:

- Installed ZTA interlacing jets on Barmag FK6-12 machines

- Upgraded to SiC air guides

Results:

- Nozzle Lifespan: Extended to 22 months

- Energy Savings: 28% reduction in compressed air usage

- Yarn Quality: Breakage rate dropped to 2.3%

Technical Specifications

| Parameter | ZTA Nozzle | SiC Air Guide |

|---|---|---|

| Material | ZrO₂-Al₂O₃ Composite | 99% SiC |

| Operating Pressure | 0.4-0.8 MPa | 0.3-0.7 MPa |

| Max Temperature | 600°C | 1,000°C |

| Compatibility | Barmag FK6/FK7 | Rieter, Toyota |

Installation & Maintenance Guide

5.1 Step-by-Step Installation

- Pre-Cleaning: Use ultrasonic cleaners to remove machining residues.

- Alignment: Laser-align nozzles within 0.03mm radial tolerance.

- Sealing: Apply high-temperature epoxy (shear strength ≥18MPa).

5.2 Troubleshooting Common Issues

- Uneven Entanglement: Check for channel blockages or pressure fluctuations.

- Air Leaks: Replace ceramic gaskets (included in E-Qo’s retrofit kits).

Industry 4.0 Integration

Our smart interlacing jets now feature:

- IoT Sensors: Monitor real-time airflow pressure and nozzle wear.

- Predictive Maintenance: AI algorithms alert technicians 2 weeks before part replacement.

- 3D Printing: Prototype custom nozzle designs in 72 hours.

Why Partner with E-Qo Tech?

- 30+ Years Expertise: Serving 50+ textile mills globally.

- Certifications: ISO 9001:2015, RoHS compliant.

- Free Samples: Test our nozzles risk-free for 30 days.

- 24/7 Support: WhatsApp/Email technical assistance.

Conclusion

E-Qo Tech’s ceramic interlacing air jets are transforming textile manufacturing through unparalleled durability and efficiency. As the industry moves toward Industry 4.0, upgrade your machinery with solutions that keep pace with technological advancements.

Act Now:

📧 Request a free sample kit: info@ceramics-tech.com