Looking for the perfect ceramic components to optimize your textile equipment?

Get Tailored Ceramic Solutions for Your Textile Machinery

As a trusted textile machinery parts supplier, we specialize in precision-engineered ceramic upgrades for spinning, weaving, and finishing systems. Whether you need standard replacements or custom ceramic components, our team delivers:

Free Sample Testing: Validate performance risk-free.

Rapid Response: 24-hour technical support & quoting.

Bespoke Manufacturing: Modify dimensions, materials, or coatings to match your machinery (Barmag, Rieter, Toyota, etc.).

Why Choose E-Qo Tech’s Ceramic Textile Components?

Superior Material Properties

Aerospace-grade ceramics with hardness >Hv1500 and friction coefficient <0.1.

Excellent thermal stability (up to 1600°C) and electrical insulation.

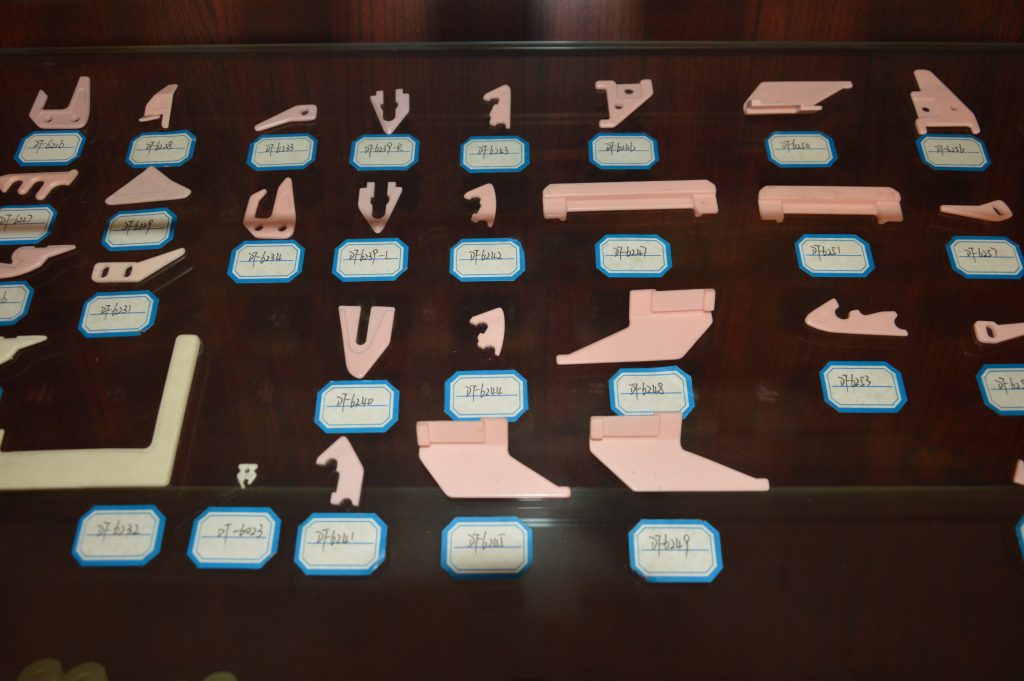

Precision Manufacturing

CNC machining and laser cutting ensure ±0.01mm tolerance for seamless integration.

Custom geometries for OEM replacements or innovative designs.

End-to-End Customization

Prototype development within 7 days.

Bulk order support with MOQ flexibility.

Certified Quality

ISO 9001:2015 certified.

RoHS & REACH compliant.

Industry Applications

Upgraded Yarn Guidance Systems

ZTA ceramic rails reduced downtime by 60% for a textile mill.

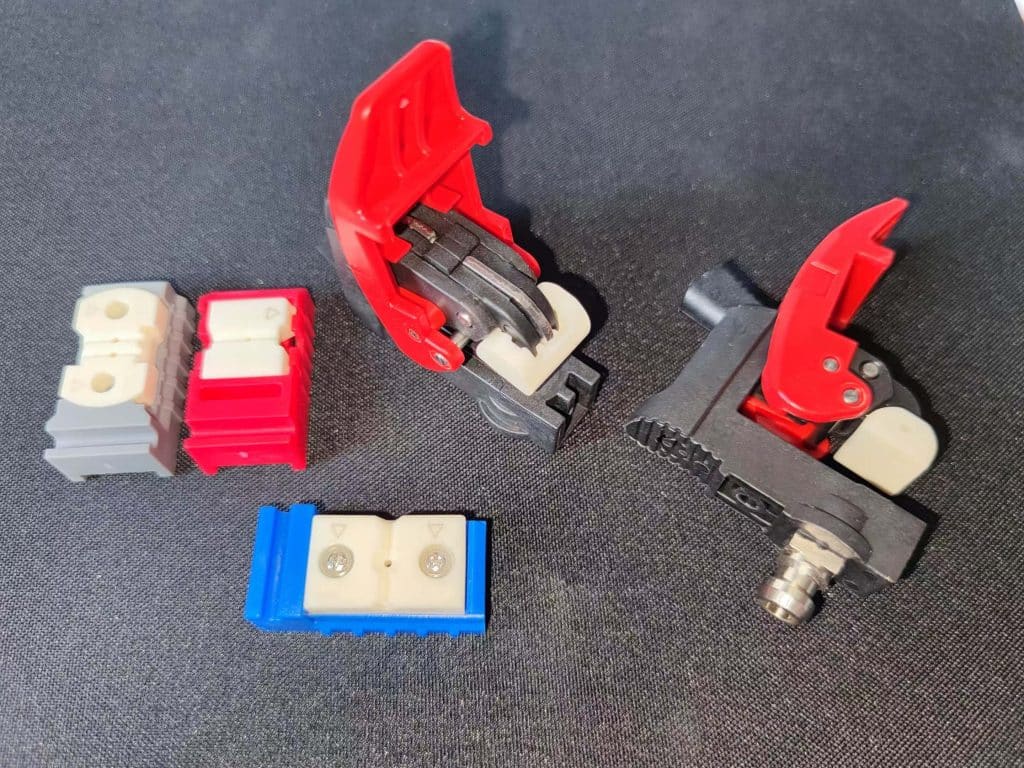

Barmag FK6 Friction Disc Replacement

Si₃N₄ discs boosted productivity by 20%.

Anti-Static Guides for High-Speed Weaving

Al₂O₃ rollers eliminated yarn static.