Introduction

The textile manufacturing industry faces relentless demands for speed, precision, and sustainability. Traditional metal components often fall short due to wear, corrosion, and energy inefficiency. At E-Qo Tech, we engineer textile machinery ceramic parts from advanced materials like alumina (Al₂O₃), zirconia (ZrO₂), and silicon carbide (SiC) to overcome these challenges. This article explores how ceramic components are transforming textile production lines worldwide.

Why Ceramics Outperform Metals in Textile Machinery

1.1 Unmatched Wear Resistance

Textile manufacturing involves constant friction from synthetic fibers like polyester and nylon. Our alumina ceramic components exhibit:

- Hardness: 1,500 HV vs. 200 HV for stainless steel

- Wear Rate: <0.1 mm³/year in abrasive fiber environments

- Case Study: A Turkish textile mill reduced guide replacement frequency by 78% after switching to our ceramic yarn guides.

1.2 Thermal Stability for High-Speed Operations

Modern machines like Barmag FK6 operate at 1,200 RPM, generating intense heat. Zirconia-toughened alumina (ZTA) components:

- Withstand temperatures up to 1,600°C

- Maintain dimensional stability (±0.01mm) across thermal cycles

- Enable 24/7 production without performance degradation

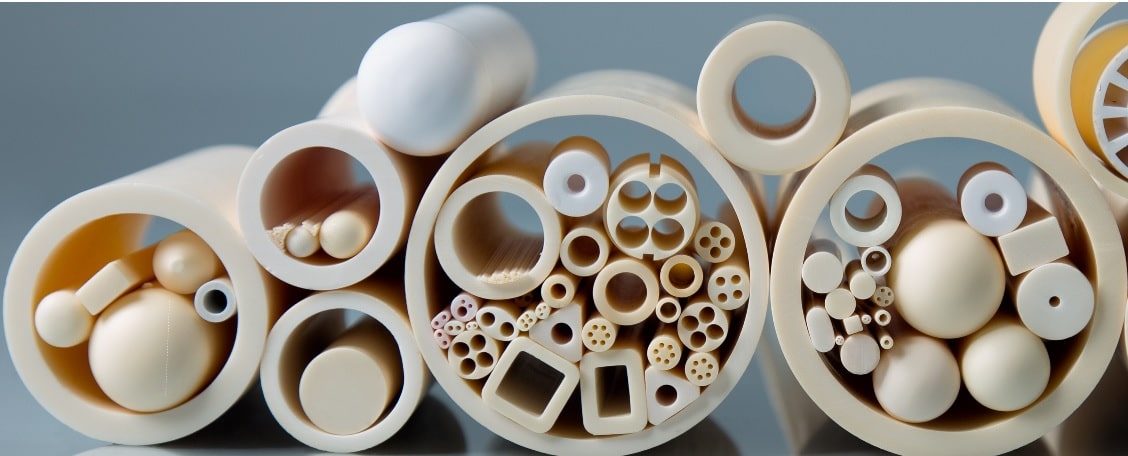

Key Ceramic Components in Textile Machinery

2.1 Ceramic Yarn Guides & Tension Controllers

- Material: 99.5% Alumina (Ra <0.2μm surface finish)

- Benefits:

- Reduce yarn breakage by 60% compared to steel guides

- Compatible with Barmag, Rieter, and Toyota machines

- Customizable groove designs for polyester/nylon blends

Explore our textile machinery ceramic parts portfolio for yarn handling solutions.

2.2 High-Speed Spinning Ceramics

| Component | Material | Performance Gain |

|---|---|---|

| Friction Discs | Silicon Nitride (Si₃N₄) | 30% longer lifespan vs. tungsten carbide |

| Hotbox Covers | ZTA Composites | 22% energy savings through thermal insulation |

| Air-Jet Nozzles | Silicon Carbide (SiC) | 15% higher airflow efficiency |

Material Science Behind Our Ceramics

3.1 Alumina Ceramics

- Purity: 95%-99.8% Al₂O₃

- Textile Applications:

- Slub catcher eyes

- Anti-static rollers

- Draw texturizing machine guides

3.2 Zirconia Composites

- Flexural Strength: 1,200 MPa (2x higher than alumina)

- Critical Uses:

- High-stress false twister components

- Corrosion-resistant valves for chemical fiber processing

Case Study: Optimizing a Barmag FK6 Line

A Vietnamese synthetic fiber producer faced:

- Frequent friction disc replacements (every 6 weeks)

- 15% yarn quality rejects due to metal particle contamination

Our Solution:

- Replaced tungsten discs with Si₃N₄ ceramic friction discs

- Installed ZTA hotbox covers

Results:

- Disc lifespan extended to 9 months

- Energy consumption reduced by 18%

- Yarn purity achieved 99.97%

Discover Barmag-specific ceramic upgrades

Maintenance Best Practices

5.1 Installation Guidelines

- Use laser alignment tools for ≤0.02mm positioning accuracy

- Apply ceramic-compatible epoxy resins (shear strength ≥20MPa)

5.2 Cleaning Protocols

- Ultrasonic cleaning with pH-neutral solutions

- Avoid abrasive brushes exceeding 200μm bristle hardness

Industry 4.0 Integration

Our smart ceramic components now feature:

- RFID tags for usage tracking

- IoT-enabled wear sensors (predict replacement timing)

- 3D-printed custom geometries (72-hour prototyping)

Why Choose E-Qo Tech?

- 30+ Years Expertise: 200+ textile industry clients worldwide

- Certifications: ISO 9001:2015, RoHS, REACH

- Customization: Modify dimensions/materials within 7 days

- Support: 24/7 technical assistance via WhatsApp/email

Conclusion

From ceramic yarn guides to advanced spinning rotors, E-Qo Tech’s textile machinery ceramic parts deliver unprecedented operational efficiency. As synthetic fiber production grows at 4.8% CAGR, upgrade your equipment with ceramics that match industry demands.

Take Action Today:

📧 Request free samples: info@ceramics-tech.com